Tipper Trailer Lifting System and Handling Precautions.

Tipper trailer hydraulic system composition

Tipper trailer is mainly composed of tractor and semi-trailer, and the main vehicle is connected by saddle and semi-trailer to form a semi-trailer train. The hydraulic lifting system of the rear tipping self-unloading semi-trailer is mainly composed of a power take-off (gearbox), a hydraulic pump, a lift valve, an air control valve, a limit valve, a hydraulic cylinder, a hydraulic oil tank, and a high (low) pressure oil pipe.

Tipper trailer hydraulic system principle

The hydraulic lifting principle of tipper trailer is as follows: the power take-off device of the main vehicle transmission is operated to drive the hydraulic pump to work. The oil pipe enters the lift valve, and the lift valve delivers high-pressure oil to the oil cylinder or drains it into the hydraulic oil tank under the control of the air control valve to realize the lifting, intermediate stop and lowering functions of the hydraulic oil cylinder.

Tipper Trailer for Sale with Best Price

Tipper Trailer for Sale with Best PriceTipper trailer hydraulic lift system maintenance specification

1. The tipper trailer for sale should be lifted slowly during the running-in period. In principle, the engine speed should be controlled at about 1000 rpm, and it should not exceed 1500 rpm after the running-in period;

2. Due to impurities such as iron filings in the hydraulic system during the running-in period of the new car, the Tipper trailer should replace the hydraulic oil and clean the hydraulic oil tank when it is lifted about 300 times;

3. The high-pressure oil pipe must be replaced every two years. If the hose is found to be leaking, damaged or partially bulged or cracked during routine maintenance, it should be replaced in time;

4. Check the hydraulic oil every week for discoloration and deterioration. If there is discoloration and deterioration, it should be replaced in time. The hydraulic oil should be changed according to the region and season. Generally, it is more appropriate to change the oil in April and October. If the oil is found to be insufficient, it should be replenished in time.

5. The upper and lower brackets of the oil cylinder should be filled with grease (butter) in time. It is recommended that the oil cylinder be filled with grease once every 120 times or every 15 days. It needs to be filled with grease again before returning to use after long-term use;

6. Check the oil return filter element and air filter element inside the hydraulic tank every half month for debris and clean it, and replace the oil return filter element and air filter element of the hydraulic tank every six months;

38 Ton 40 Cbm Tipper Trailer for Sale Near Me

38 Ton 40 Cbm Tipper Trailer for Sale Near MeTipper trailer lifting operation and precautions

1. Tipper trailer lifting operation sequence: open the tarpaulin or box cover of the compartment, open the rear door locking device, step on the clutch and wait for 5 seconds when the gearbox is in a neutral state, combine the power take-off, and switch to a low gear (below 4th gear) ), put the handle of the air control valve in the up position, release the clutch and the vehicle starts to lift, you can step on the engine accelerator properly but it must be controlled within 1500 rpm, when the cylinder reaches the maximum stroke or the limit valve works, put the handle of the air control valve in the up position Stop position.

2. Tipper trailer descending operation sequence: depress the clutch and wait for 5 seconds, disengage the power take-off, disengage the transmission gear, release the clutch, and slowly turn the handle of the air control valve from the stop position to the descending position (turn over after the great luck) The air control valve of the hydraulic lifting system of the unloading semi-trailer is a proportional control valve, which can control the descending speed of the oil cylinder. The closer the handle is to the descending position, the faster the descending speed of the oil cylinder). stop position.

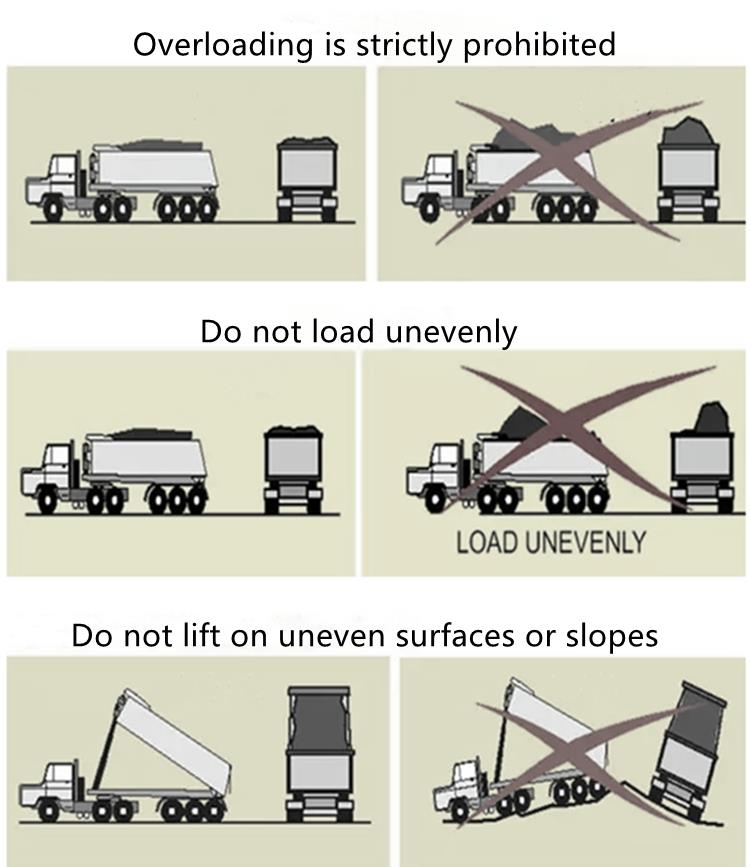

3. Precautions for Tipper trailer lifting operation

Tipper trailer hydraulic cylinder is a special cylinder for lifting. It is strictly forbidden to use the cylinder as a stable support for the car body; the time when the cylinder is exposed to the air in the lifting state shall not exceed 2 hours (not more than 30 minutes in humid air), otherwise It will cause oxidation and corrosion of the cylinder.

It is strictly forbidden to disassemble and adjust the relief valve on the lift valve, otherwise the hydraulic system will lose its safety protection function and cause an accident; 38 ton tipper trailer ensures that the front and rear and left and right loading are evenly loaded when loading goods. Loading the goods too far forward will cause the hydraulic system to overload. Loading the goods too far back will cause the vehicle to overturn when unloading, and the eccentric load on the left and right of the goods will easily strain the oil cylinder and rollover.

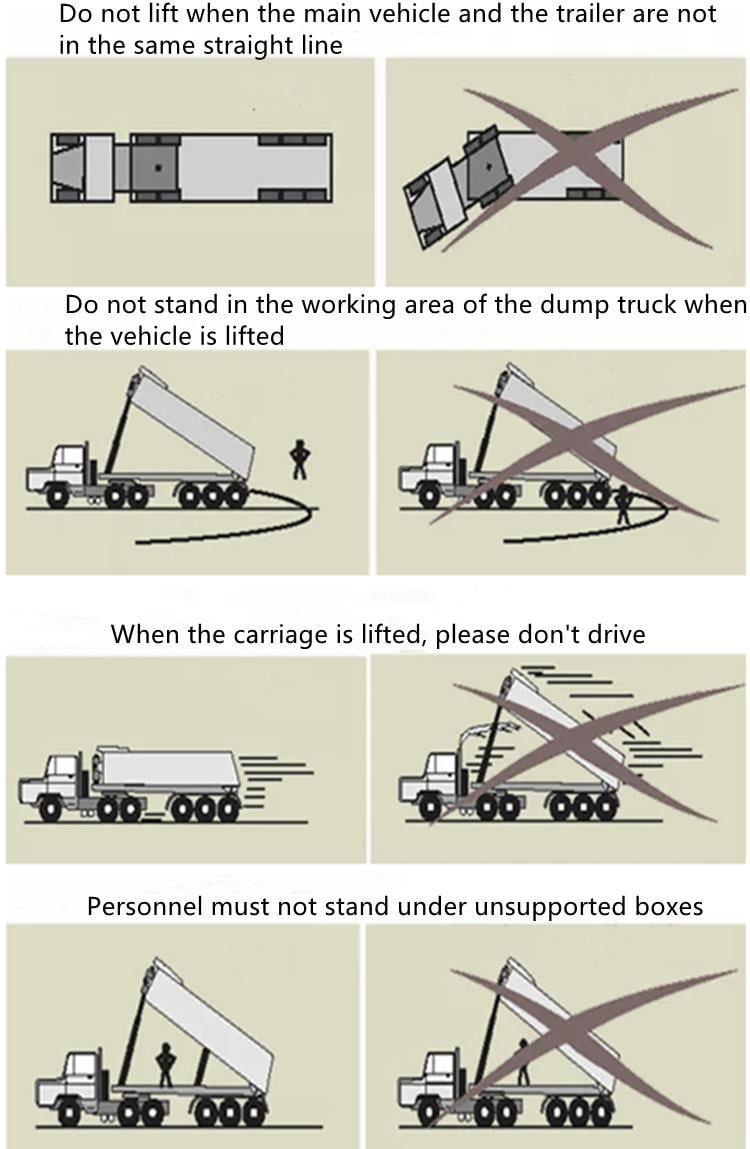

When unloading the Tipper trailer, make sure that the unloading ground where the vehicle is located is firm and flat, that the vehicle is level, and that the main vehicle and the trailer are in a straight line.

Tipper trailer lifting operation and precautions

Tipper trailer lifting operation and precautionsDuring the lifting operation, the operator cannot leave the operating position, and it is strictly forbidden for anyone to stand or walk in the working area; the operator must pay attention to the influence of the lateral wind because the longer side wind of the tipper trailer acts on the car body Surface forces can cause a rollover.

The cargo carried by the tipper semi trailer should not be higher than the rear door as much as possible (unless it can be guaranteed that it will not block the rear door), and the rear door locking device must be opened before lifting and unloading, otherwise, the cargo will be crowded at the rear of the vehicle during unloading and overturn.

When unloading the cargo when the temperature is below 0 degrees, be sure to pay attention to whether the cargo is frozen, otherwise the tipper trailer will rollover due to the imbalance between the left and right when unloading the cargo; do not move the vehicle when the carriage is lifted, and do not use sudden braking. Unload sticky goods, otherwise it will cause the vehicle to roll over or damage the cylinder.

If the lift angle of the car body reaches about 25 degrees (the car has been lifted halfway), and the cargo in the car has not been unloaded, be sure to stop the lift and check the cause of the sticking.

if you feel that it may roll over when lifting Be sure to stop lifting and lower the car body slowly; after the car body has completely dropped for about 30 seconds, be sure to put the handle of the air control valve in the middle stop position, and do not start the car in the lowered position, so as to prevent all the hydraulic oil in the hydraulic cylinder from returning to the hydraulic pressure Cavitation of the fuel tank and fuel injection of the fuel tank are caused in the fuel tank; when the vehicle needs to be lifted during maintenance or maintenance, please make sure that the vehicle is safely supported. Working under an unsupported vehicle will endanger life.

Tipper trailer lifting operation and precautions

Tipper trailer lifting operation and precautions

Comments

Post a Comment