Table of Contents

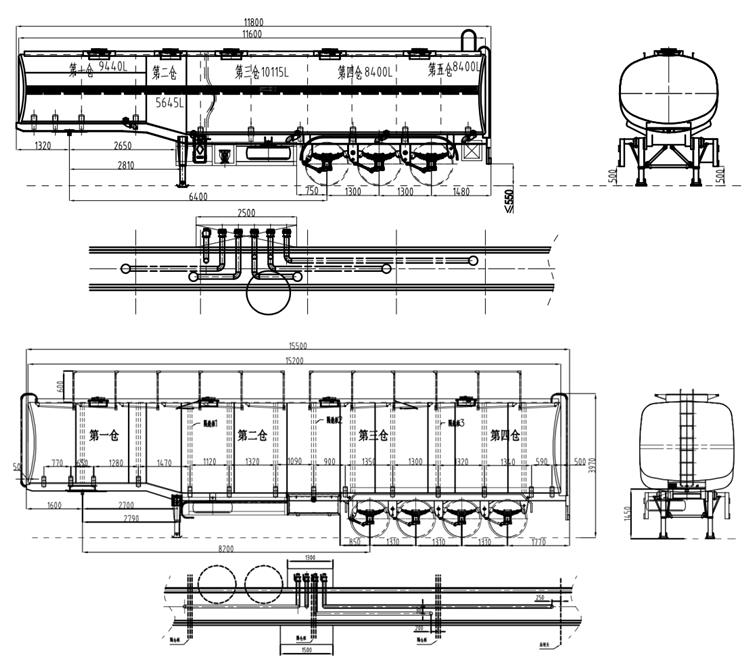

Chapter 1. TITAN Fuel Tanker Trailer for Sale Specs, Capacity, Dimension and Drawing

Chapter 2. Why do Fuel Tanker Trailers for Sale have Several Compartments?

Chapter 3. New and Used Fuel Tanker Trailer Parts

Chapter 4. How to Drive a Trailer Safely? | Use Fuel Tanker Trailer for Sale Correctly and Safely

Chapter 5. How to Maintain Fuel Tanker Trailer for Sale

Chapter 1. TITAN Fuel Tanker Trailer for Sale Specs, Capacity, Dimension and Drawing

TITAN manufactures high-quality 45000 liters fuel tanker trailers normally for diesel fuel, petrol, crude oil, edible oil, palm oil and liquid bitumen. widely used in various transportation units, gas stations and other logistic industries.

TITAN 45000 liters fuel tanker trailer for sale adopt advanced design concept. We can customize the tri axle fuel tanker trailer for sale for you according to your request. And we TITAN offer carbon steel, stainless steel, or aluminum alloy material tanker trailers. To fabric the most durable tankers, especially for Africa Market, considering the road condition.

Specification

Shape: Round or square

Dimension: 12000mmx2490mm x3990mm (the exact size depends on the final design.)

Tare Weight (semi trailer): About 8000-12800kg

Total volume(m³): 25-60m³

Tank Body Material: 5mm or 6mm/Q235 carbon steel

End plate: 5mm or 6mm/Q235 carbon steel

Manhole Cover: Carton steel or Aluminum alloy API manhole cover 500mm (diameter)

Bottom Valve: Aluminum API Pneumatic Bottom Valve

Compressor: BOHAI 10m³/12m³ or other brands

Discharging Valve: Diameter is 3 or 4 inch

Compartments: Optional

Discharging Pipe: 4 inch rubber hose,2pcs,6m/each

Cat Walk: With (common model or special design)

Main beams: Welded design or special design I beam, connected by bolts and nuts Q345 carbon steel material

Axle: 2 or 3 or 4 axles,12T/13T/16T,BPW/ FUWA/ TITAN brand

Landing Gear: JOST(D200T) or China brand 28T

Kingpin: JOST 2.0 or 3.5 inch bolt-in king pin

Suspension: Mechanical suspension /Germany or America type /Air Suspension

Leaf Spring: 90(w)mmx13(thickness)x10layers or 10mm x12mmx12 layers

Pneumatic Braking System: WABCO RE 6 relay valve; T30/30+T30 Spring brake chamber(TKL brand); 45L air tank

Rim: 9.00-22.5/8.00-20/8.5-20 Chinese brand

Tire: 12.00R22.5/315.80R22.5/11.00R20/12.00R20 brand can be optional

ABS: Optional

Painting: Sandblasted, anti-rust chassis surface is available with 1 layer of anticorrosive primer and 2 layer of top coats.

Accessories: One standard tool box

Shipping Terms: By bulk cargo, RORO or 40HQ containers

Oil gas recovery system: Reduce the pollution of oil and gas, change the oil and gas from gas to liquid, and then change to gasoline to achieve the purpose of recycling. Electrostatic eliminator: Containing a number of thick copper wire, conductive properties, high-quality rubber.

WABCO emergency valve, high braking performance& ensure driving safety. JOST E 100 Landing gear, durable quality than other ordinary landing gear. 16 ton brake pads, can improve 20% brake performance than 13 ton brake pads. Anti-skid metal grilles walk-way can be done as customer's requirements.

LED light with a protective cover, keep it from damage and steal. Explosion-proof manhole, keep normal tank pressure, ensure transportation safety

Tank material: carbon steel, stainless steel, aluminum alloy material.

Tank volume: 30 cbm to 90 cbm according to your demands.

Axle: 2 axles to 4 axles.

Suspension: mechanical spring suspension, air suspension, center point bogie suspension.

Compartments: 1 compartment to 7 compartments.

Loading Mode: top-loading or bottom loading mode

Chapter 2. Why do Fuel Tanker Trailers for Sale have Several Compartments?

Many 3 axle fuel tanker trailer for sale are capable of transporting various liquids simultaneously. These 45000 liters petrol tankers use several compartments and are capable of transporting a variety of liquids, including industrial chemicals, concrete, diesel, milk, gasoline and water.

Each individual liquid has a different density, which alters the tanker’s maximum carrying capacity. Although tri axle Fuel tanker trailer for sale vary in size, the tankers all have the same distinct shape that provides maximal storage capacity.

Fuel tanker trailer for sale use highly technical equipment to ensure the process of loading, transporting and offloading the fuel product is as safe and wasteless as possible. Many Fuel tanker trailer for sale are fitted with special devices that read the quantity of fuel being loaded, control pressure, and even regulate temperature!

A specific type of hose is used during the process of loading and offloading the fuel. These hoses are designed to fit the opening on the tankers and usually have gaskets and seals in place to reduce and limit the amount of potential spilling.

During the loading process, the vapor of the fuel is carefully monitored as these gases are highly flammable. Once loaded, the trucks are secured for travel and can head off to their destination, which is fitted with the same type of hose to properly offload the fuel.

Fuel tanker trailer for sale are vehicles with large tanks for transporting liquids. They are designed for specific cargos and service requirements and are built in a range of sizes. Fuel tanker trailer for sale are equipped with a pumping system for loading and off-loading liquids.

Chapter 3. New and Used Fuel Tanker Trailer Parts

Anti-overflow sensor

The anti-overflow electronic sensor is widely used in various types of container tanks when the liquid is sealed and filled, when the liquid is about to be full, a safety device that will give an alarm in advance. Its installation position is on the top manhole cover of the container. When the oil level reaches the warning limit, the sensor will automatically alarm and switch off.

Oil and gas recovery system

The fuel tanker trailer has an oil and gas recovery system. The main function of the fuel tanker trailer is to realize complete closed gas recovery during the loading and unloading process of the fuel tanker trailer and limit the emission of oil and gas into the atmosphere. When the fuel tanker trailer is being unloaded, the oil and gas from Li Mina in the gas station can be returned to the tanker through the gas return line, and then the oil and gas can be brought back to the tanker for processing through the tanker. The purpose of oil and gas recovery.

Subsea valve

The submarine valve is also called the emergency shut-off valve, mainly for safety. It is generally installed at the bottom of the tank. It can replace the traditional top-loading refueling for bottom-loading refueling, making it more convenient and environmentally friendly and safe for the staff to operate. When an accident occurs in the fuel tanker trailer, the submarine valve will be disconnected, and the under-vehicle pipeline will be cut off from the tank body without affecting the tank's sealing. This can effectively prevent the oil in the tank from being discharged and ensure tank Security.

Safety valve

The safety valve is mainly designed for tank products such as oil tanks and chemical tanks. Different opening pressures are set according to user needs to meet different needs. The main body is made of integral stainless steel precision casting, corrosion resistance, high sealing, suitable for various environments.

Breathing valve

The purpose of the breathing valve is to prevent oil leakage. When the breathing valve is tilted to 70o, the sealing ball inside the breathing valve will form an effective seal.

Oil gauge

The oil dipstick is mainly installed at the prepared opening of the manhole cover, where you can pretend the dipstick or level gauge.

Chapter 4. How to Drive a Trailer Safely? | Use Fuel Tanker Trailer for Sale Correctly and Safely

1. Every driver who drives a fuel tanker trailer must do routine maintenance of the tanker. He must do a good job of checking, cleaning, tightening, and adding before, during, and after the delivery. Car storage problems or security risks, so that timely detection of problems in a timely manner;

2. Check whether the 45000 litres fuel tanker trailer body, pipe network, valves, etc. are leaked or leaked before exit. Whether the upper cover is properly covered or not, the amount of lubricating oil, the amount of fuel oil, the cooling water, the braking of hands and feet, and the steering device, Meters, lights, tire pressure, tire nuts, etc.

3. Problems that driver’s friends should pay attention to while driving the tanker:

The fuel tanker trailer checks the working condition of each instrument while driving;

Check if the steering system is working properly when the fuel tanker trailer is in motion;

It is abnormal for the fuel tanker trailer to check the hand and foot brake while driving.

The tri axle fuel tanker trailer for sale checks whether the engine, the chassis and the tank body are abnormal noises and abnormal odors during running.

Use the parking time to do the following inspections of the tanker: Check whether the brake drums of the front and rear wheels are overheated, check the tightening of the tires and nuts, remove the inclusions in the tire tread, and check for oil leakage or water leakage. , leakage, check the situation of the leaf spring, whether the shaft bolt is loose, check the appearance of the oil tank and the tank network system of the tanker;

Fuel tanker trailer regularly goes to the service station to do chassis maintenance and maintenance work to remind drivers in general to strengthen the routine maintenance of 45000 litres fuel tanker trailer and to regularly check and change the fire extinguishers on the vehicles in case of any accidents.

Chapter 5. How to Maintain Fuel Tanker Trailer for Sale

1. Regularly check whether the wiring posts in the electric control cabinet are loose, whether the wires are worn out during shipment, eliminate dust, and avoid damaging parts.

2. Daily maintenance of Bitumen tanker trailer, transfer pump and other motors, agitators and valves shall be carried out in accordance with the regulations in the factory manual.

3. If the equipment is out of service for a long time, there should be liquid in the fuel tanker trailer and pipeline, all hole covers should be tightly closed to keep clean, and all moving parts should be filled with lubricating oil.

4. The fuel tanker trailer should regularly check the matching clearance between its stator and rotor, and consider replacing the stator and rotor when the minimum clearance specified by the machine cannot be reached.

5. After the end of each shift, the fuel tanker trailer should be cleaned, as well as the asphalt tanks without insulation and anti-corrosion facilities, as well as the asphalt pumps, emulsifiers, aqueous solution pumps, and pipelines.

Fuel tanker trailer for sale has gradually become the 45000 liters fuel tanker trailer commonly used in major industries. Its ultra-high performance has been universally recognized by the majority of users, but users must do the corresponding maintenance and repairs when using the 3 axle fuel tanker trailer. Maintenance work, because can effectively extend the service life of the oil tank.

Comments

Post a Comment